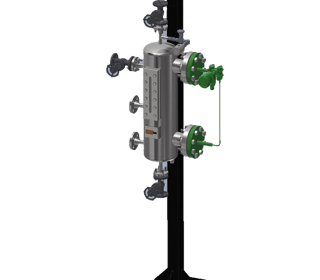

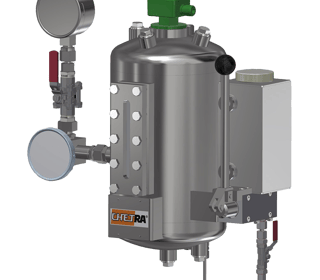

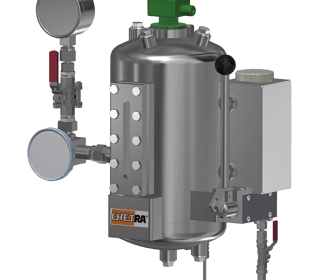

Plan 52,53A

Thermosiphon System

Plan 52,53A

API 682 4th Ed.

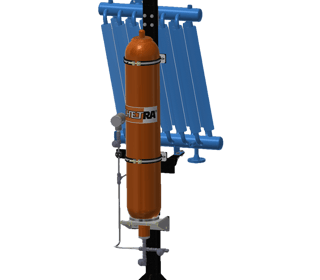

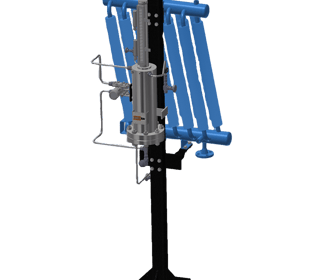

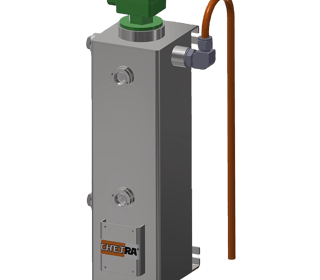

CHETRA thermosiphon system provides leakage compensation and cooling of the mechanical seal. Circulation is by the thermosiphon principle or forced circulation by means of a circulation pump or conveyor system.

Level and pressure monitoring (Plan 53A) prevents dry running and monitors (product) leakage.

Versions:

- Available with dished ends and straight ends 6L, 9L and 12L and with different pressure levels

- Instrumentation according to customer and process requirements

- Standard container made of 1.4571 with borosilicate glass

- Sterile version for pharmaceutical and food industries

- Individual material combinations, instrumentation and designs

- DGRL/PED 2014/68/EU – ASME approval on request